It has been believed that AQL, i.e. the borderline quality level (usually misunderstood in companies), which is used for quality acceptance of batches of products, exhausts the subject of random checks using the alternative method.

Indeed, the “famous” AQL is indicated as the basis for the selection of inspection plans by the most popular ISO 2859-1 standard ( “1” is important), used in the case of quality acceptance of subsequent batches of products (deliveries or shipments). With the use of this standard, based on the AQL level agreed between the parties to the transaction, the so-called control plans (the control plan is nothing more than an “instruction” on how much “n” sample should be taken for inspection and when, based on the results of the control of this sample, to accept and when to reject the batch). But these AQL based plans do not exhaust the use of alternative sampling procedures in practice. A very little known application area of this control are the procedures described in ISO 2859-4 (“4” is important).

The fourth part of the ISO 2859 standard presents the so-called procedures for assessing the declared quality levels, which allow to assess the quality of virtually any processes. And what is interesting in the context of their practical use in the field of quality management (e.g. continuous improvement, FMEA analysis, planning internal audits) are not limited to the assessment of products very narrowly understood as “manufactured items”, but allow the quality assessment of virtually any process results. This is already evidenced by the examples of applications presented in the standard:

There are only two examples of the use of the ISO 2859-4 standard above, but it can already be seen that the possibilities of its application are much wider than just the assessment of production quality. In this standard, the key element is the so-called DQL (Declared Quality Level), which is then confirmed by appropriate methods. This is somewhat the equivalent of the well-known AQL found in “traditional” receiving routines.

Very interesting prospects for the use of ISO 2859-4 appear in the field of the idea of quality improvement (and it does not matter whether we are talking about systems based on ISO 9001, IATF 16949 or, for example, about the Six Sigma methodology). In practice, there is often a need to assess whether the implemented improvement measures were actually effective. It is worth referring to the latest edition of the standard describing the FMEA analysis (AIAG & VDA ed. 1 + errata), which even requires that you collect evidence (literally – evidence) for the effectiveness of the implemented actions.

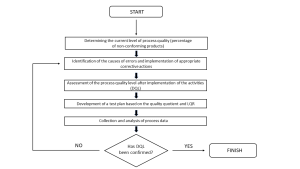

The scheme of pro-quality procedures using ISO 2859-4 is very universal

Pic. 1. Extended procedure for confirming DQL

Source: own study

As my favorite quality management expert, W.E. Deming once said: “We only believe God, everyone else has to bring the data.”

And here you go – we have the data!

Author: Tomasz Greber [PROQUAL]

PROQUAL Management Institute

B. T. Greber Spółka Jawna