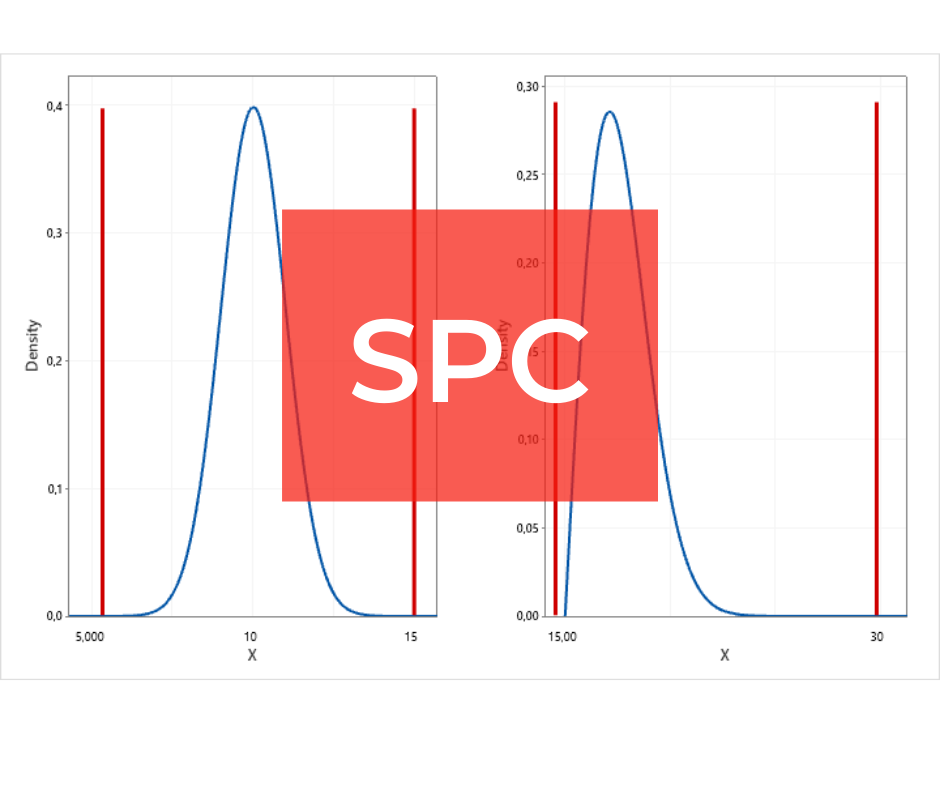

The major part of the training are workshops consisting the analysis of inspection results with the use of SPC tools. Training participants create and analyze control cards (based on real data). They also learn to use ability indices as practical as possible – if possible on their own data.

CONTENTS:

CONTENTS:

EXERCISES:

CONTENTS:

EXERCISES:

CONTENTS:

EXERCISES:

CONTENTS:

EXERCISES:

During the training, several exercises are carried out, including: calculating basic process statistics, testing the normality of the distribution of results, creating and analyzing control charts, calculating and analyzing the capabilities of processes and machines (including Cp and Cpk).

Participants will receive worksheets that they can later use as part of their company’s statistical process control application.

After the training, each participant will receive a certificate confirming completion of the training.

People responsible for the use and development of the use of statistical methods to control processes. Technologists, process engineers and quality management representatives.

PROQUAL Management Institute

B. T. Greber Spółka Jawna